Get The Best Laser Cutting Tips With The Top Welding And Fabrication Experts

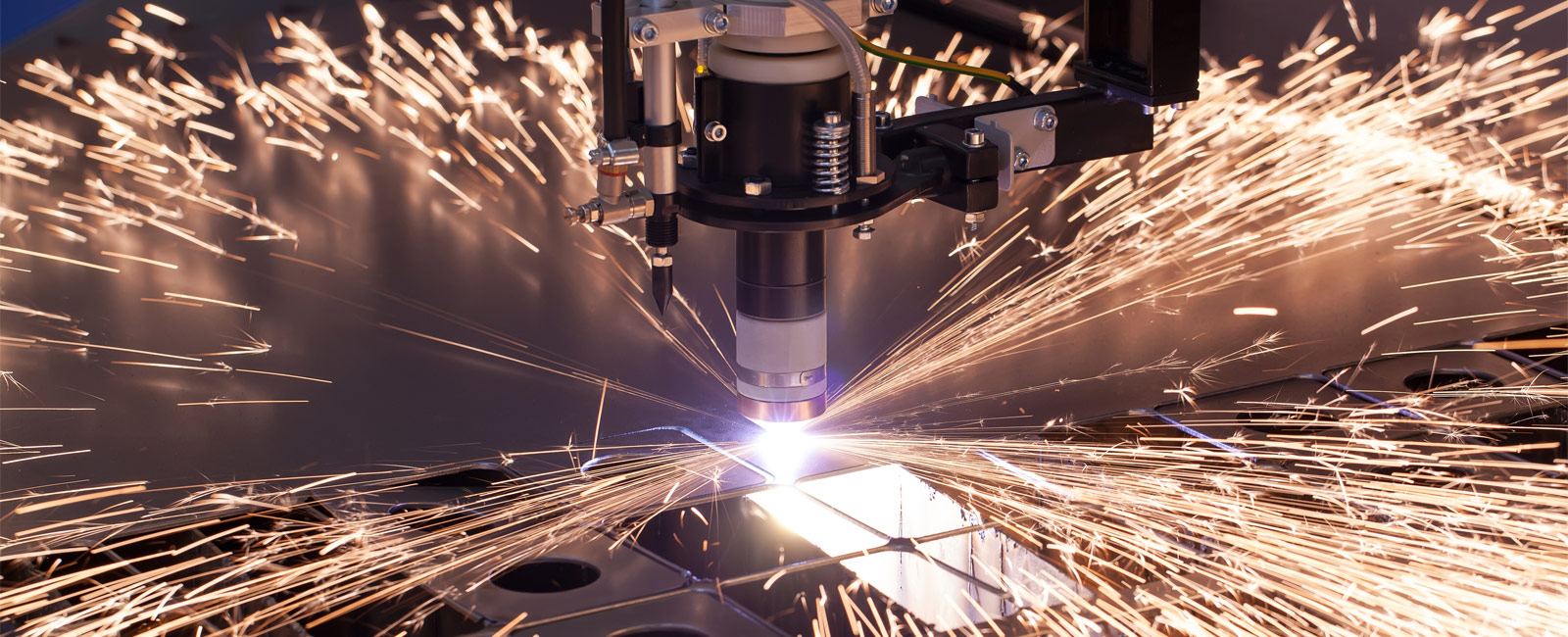

Laser cutting and engraving is one of the most ideal methods that any top class machining and welding company will use to cut a number of metallic materials for manufacturing, fabrication, or any other industrial application.

It operates by directing a high powered laser on the metallic sheet that’s meant to be cut to leave it with a high quality surface finish. Here are some of the top tips for getting the most out of laser cutting services.

Always watch out for the type of material that you’re using. If you are using a Trumpf 3030 machine for instance your optimal material’s thickness should be 20mm for mild steel, 8mm for aluminum, and 12mm for stainless steel – know your machine and its ideal material.

Know the speed you need to achieve the best results. Usually the speed of a laser machine can be altered to ensure that only a minimum amount of de-burr is sustained by thick materials so don’t brush off the need for ideal speed.

Use the right type of software. In order to speed up the production process you must have the right types of files. DXF files are usually awesome since then can be easily transferred to a CNC Trumpf Laser Machine.

Keep a keen eye for value nesting. Working with a laser cutter needs cost effective results. To get this you will need to nest the parts correctly onto a sheet.

Laser cutting is only a single method among many others that top machining, welding, fabricators, or lineboring experts will use to give you the best fabrication results.